Dongguan city, kingda plastic insulation board co., LTD

Contact: manager zhao

Mobile phone: 13509011897

Telephone:

Fax:

Email:1440816890@qq.com

Website:www.qdjnkj.com

Address: Zhongtang town Zhancui Nan di Industrial area

1、 Material selection:

The basic properties of the material must be small bulk density, high compressive strength, low water absorption, easy to pave and paste, easy to control the compactness of the pavement, and consider the technical requirements of layered laying. The quality of materials is required to be high.

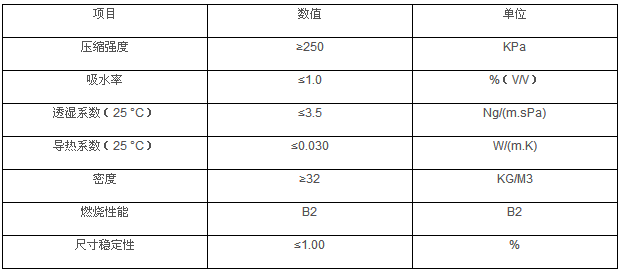

2、 Industriously reach the performance index of extruded board.

Qinda extruded board has the characteristics of high compressive strength (the maximum compressive strength can reach 50 tons per square meter), low water absorption (closed hole structure material, theoretical water absorption is zero), long service life (the main performance index retention rate in 50 years is more than 70%), etc., which is more suitable for earthwork construction replacement in green fill engineering. It has been widely used in Shanghai Nanjing Expressway, Qinghai Tibet railway and World Expo project.

The main performance indexes are as follows

3、 Construction precautions:

1. The selected materials must meet the national standards and meet the important technical indicators such as bulk density, compression resistance, water absorption, etc.

2. If the replacement earthwork of light material is located below the groundwater level, the anti floating counterweight requirements shall be considered.

3. To ensure the replacement thickness of light materials and achieve the best economic benefits. It is necessary to ensure the thickness of the upper earthwork modeling. To ensure the growth of green plants. Generally, the soil layer shall not be less than 2m.

4. It is necessary to pay attention to the high-level control of replacement soil, material connection mode, laying arrangement mode, etc.

5. The extruded board can be cut according to the construction needs, but the area after cutting shall not be less than 0.3m2. The length of one side shall not be less than 0.5m.

6. In order to ensure the stability of the shape, the plates should be staggered and stacked.

4、 Construction technical process:

1. Excavate earthwork according to the pile height and the replacement height of Qinda XPS board. Determine the earth excavation bottom.

2. Before the Extrusion board is laid, the concrete cushion construction shall be carried out first, and the thickness of 100mm is C20 concrete. 100mm gravel cushion at the bottom is used as water filtering measures. During the pouring and tamping of cushion, 10 m separate warehouse joints shall be reserved between adjacent zones, at places with obvious elevation changes, and in large area of cushion. Ensure the internal drainage after the whole XPS is placed.

3. Control axis shall be formulated according to regional trend.

4. Lay the Qinda XPS board layer by layer along the axis direction. (the specific laying shape is based on the construction design)

5. After laying, it can be directly covered with soil on the plate. It can be covered with a non-woven protective layer.

5、 The advantages of Qinda extruded board are replacing large area earthwork, reducing ground load, accelerating construction progress and reducing construction cost. The use of high-quality XPS with the same service life of the building can significantly improve the overall quality of the building.