Dongguan city, kingda plastic insulation board co., LTD

Contact: manager zhao

Mobile phone: 13509011897

Telephone:

Fax:

Email:1440816890@qq.com

Website:www.qdjnkj.com

Address: Zhongtang town Zhancui Nan di Industrial area

The specific method is:

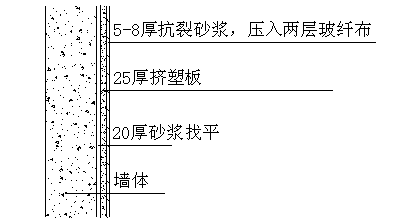

1. XPS polystyrene plate: 25 thick 600mmX1200mm shall comply with the provisions of GB/T 10801.2-2002 "extrusion polystyrene foam plastics for thermal insulation"

A, the material

1. XPS polystyrene plate: 25 thick 600mmX1200mm shall comply with the provisions of GB/T 10801.2-2002 "extruded polystyrene foam plastics for thermal insulation"

2, adhesive. Anti-crack mortar: a single component, the performance indicators meet the requirements of the current standards.

3. Plastic expansion nail: made of super tough polyamide plastic, with a large diameter riveting head, used for hollow brick wall, the tail shall be equipped with a back twisting mechanism.

4. See table 5 for the main technical performance indexes of alkali resistant fiberglass mesh cloth

|

project |

unit | indicators |

|

Mesh density (longitude and latitude) |

Number of holes/100mm |

25 |

|

Mass per unit area |

g/m2 |

≥160 |

|

Tensile damage (longitude and latitude) |

N/50mm |

≥1000 |

|

Alkali tensile strength retention rate (longitude and latitude) |

% |

≥80 |

|

Plastic coated quantity |

g/m2 |

≥20 |

3, 3, bonding operation condition by bonded box point method, a grey with 7 to 10 mm thick advisable, thickness, as shown in the detail of the extruded plate paste surface should be on the surface of wool, wipe again adhesives, paste in the tool to the wall extrusion keeps paste agent by around 10 to 3 thick thick pressure, ensure uniform paste material distribution, the actual area of paste shall not be less than 40% of the plate.

4. When pasting the plate, the flatness and perpendicularity should be checked at any time with 2m ruler and line plate. When sticking the board, pay attention to remove the overflow of the board adhesive mortar, so that there is no "meeting dust" between the board and the board, the board seam fitting is strict, the width of the seam exceeds 2mm with the corresponding thickness of polystyrene board filler, the difference in the height of the joint is not greater than 1.5mm, otherwise with sandpaper or special Angle grinder polishing level.

Ii. Construction process

Basic wall cleaning (interface treatment) -- preparation of binder -- paste edge plate turn over cloth -- paste extruded plate -- install fixed expansion nail -- preparation of anti-crack mortar -- paste fiber mesh cloth -- wipe anti-crack mortar.

Iii. Operating conditions

1. The wall leveling layer has been completed, and the vertical and leveling base shall meet the requirements of the specification within 4mm; Adhesive surface strength should meet the design requirements.

2. The surface of the basic level shall be cleaned up with floating dust and oil.

3. The door and window frames on the outer wall, the pipes through the wall for the equipment, the pipes on the wall inside the outer wall and the groove boxes should be installed in advance, and the thickness of the insulation layer should be prepared.

4. Construction equipment and transportation equipment shall be fully prepared and run normally.

Construction method

(I) preparatory work before construction

1, before the insulation, the wall should be clean, no oil, dust, dirt, weathering, paint, waterproof agent, soil and other pollution, no cracks, the overall solid, to ensure the quality of the insulation.

2, the door, the window frame around the application of insulation mortar layer plug.

3. Construction machines and tools: forced mortar mixer, horizontal transport trolley, portable mixer, bucket, scissors, roller brush, spade, hand hammer, etc.

Commonly used detection tools: by the ruler, line plate, square ruler, probe, steel ruler, etc.

(2) hang the reference line

Hang the vertical datum line at the Yin and Yang Angle of the building wall and other necessary places, and hang the horizontal line at the appropriate position of each floor to control the perpendicularity and flatness of the polystyrene board.

(3) to prepare paste mortar and paste turn-over mesh cloth

First pour the right amount of water into the bucket, add binder powder to stir, stirring must use special electric stirring equipment; After the dry powder is added and mixed evenly into a paste, the mixture can be used after 1 minute. The prepared binder should be used up within the specified time.

Where the pasting polystyrene plate side exposed (such as expansion joint, settlement joint, temperature seam and so on both sides of the seam, thermal insulation end, door window, etc.), should be done mesh cloth turn-over treatment, turn-over mesh cloth total width of 200mm+ polystyrene plate thickness.

(4) paste polystyrene board

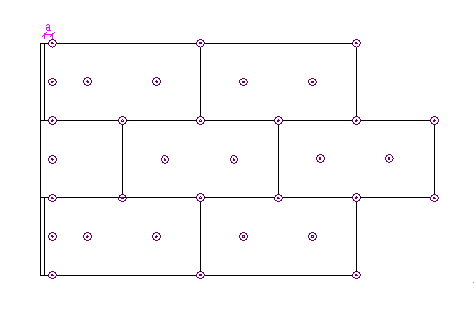

1. Firstly, set up the wall layout, and accurately determine the position of the pasted board according to the size and process requirements of XPS extruded board. The standard size of polystyrene plate is 600mm×1200mm. The non-standard size can be cut on site, but the incision must be perpendicular to the plate surface.

2, when the plate should be pasted from the top down, from left to right in the order, the plate must be transverse paste, adjacent two vertical staggered seam, the wrong seam spacing should be plate length 1/2, the minimum is not less than 200 mm.

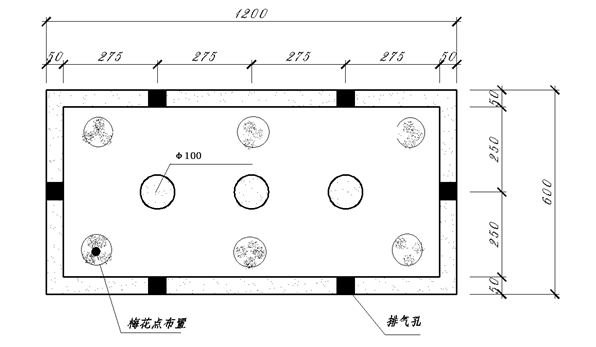

3, the bond according to the box point method bond, the ash thickness to 7-10mm thick is appropriate, as shown in detail, the extrusion board paste surface should be the surface of the hair, then wipe paste, paste with tools to the wall extrusion paste from 10 thick pressure to 3 thick about, to ensure the paste material distribution, the actual paste area shall not be less than 40% of the board.

5, for the door and window opening corner position, the application of the whole plate cover cut and paste edge straight, flat, never allowed to use pieces of plate collage.

6. Paste at the Angle of Yin and Yang, and interlock the stubble.

(v) secure the expansion nail

After the insulation board is pasted, the installation of anchorage parts can be carried out 24 hours later. During installation, the joints around each insulation board and the middle of the board shall be perforated with an electric hammer. Procedures according to relevant national insulation system technology, anchor bolt using Φ 8 expansion tube, drill hole depth is 120 mm (including the insulation layer thickness), the anchoring depth of about 50 mm above in the grassroots. The number of anchoring parts shall be determined according to the height of the floor and the nature of the base wall. The number of anchoring parts shall be appropriately increased around the Yang Angle and the window opening. The position of the anchoring parts shall be no less than 50mm from the edge of the window opening. For plates with an area of more than 0.1m2, anchoring parts should be added to fix them in the middle. For plates with an area less than 0.1m2, anchoring parts should be added to fix them if they are located at the edge of the base. The head of the anchoring part should be slightly lower than the insulation board, and timely use the plastering polymer glue to smooth, to prevent rain infiltration

1) number of fixed parts

A) 1-8 floors: no less than 6 anchoring pieces per square meter

B) 8 ~ 18 floors: no less than 8 anchoring pieces per square meter

Note: the anchorage can be increased or decreased according to the specific requirements of the tenderee.

Fixed parts installation is the XPS paste reinforcement quality, safety on an important guarantee measure, the screw must be used in the operation of electric or manual screwdriver screwed in, can never be used to hammer directly flat.

(6) anti-crack mortar layer construction

Anti-crack mortar powder material: water according to 2.5:1 (weight ratio) with mortar mixer or hand blender mixing, according to the proportion of water in the container first, and then slowly pour the anti-crack mortar powder, at the same time with an electric mixer to stir evenly paste can be used well, anti-crack mortar after a good match, shall not be any water in the course of using, should be finished within 1.5 h.

Anti-crack mortar the first time to wipe the thickness of 1-2mm, and then vertically put the grid cloth into the mortar, and then from the middle to the surrounding wipe pressure, overlap transverse no less than 8cm, longitudinal no less than 10cm, it is prohibited to dry, should be flat without wrinkles, the full degree of 100%.

For the second time, the anti-crack mortar is applied flat compaction, the grid cloth is better than dark grid, and then pressed into the second layer of grid cloth, finally, the anti-crack mortar plastering layer, the total thickness of 5-8mm, surface layer should be smooth compaction.

Where there is a reinforcing layer of mesh cloth, the reinforcing layer shall be constructed before the construction of standard layer mesh cloth.

Then the door and window openings four corners to add a strengthening of alkali mesh cloth 200×300 mm, and along the horizontal direction of the edge of the edge of the paste mesh cloth, and the net cloth into the mortar.

Network cloth paste lapped transverse for 100 mm, vertical for 80 mm, in the Yin corner position should turn 100 mm, Yang corner should turn 200 mm.

Five, construction matters needing attention

1. The minimum ambient temperature at the operating site shall be no less than 5 degrees, and the wind shall be no more than 6 degrees.

2. After the completion of the construction, attention should be paid to the protection of finished products. Avoid bumping against the wall and water immersion, and keep the indoor ventilation and dry. After the completion of each construction, to timely clean the construction tools and mixing equipment, so as not to affect the next use.

Protection of finished products

1. The residual mortar in the wall, drip tank, door window and other places after construction shall be cleaned promptly.

2, lifting crane blue should prevent collision, the finished wall insulation, other types of work shall not damage the wall, is strictly prohibited to step on the window.

3. Do not scribble on the finished wall.

4, the insulation layer, crack resistant layer, decorative layer before drying to prevent water shock, impact, vibration.

5. The construction leader shall strictly supervise and inspect the workers in the construction scope, and make the finished product protection education before the shift.