Dongguan city, kingda plastic insulation board co., LTD

Contact: manager zhao

Mobile phone: 13509011897

Telephone:

Fax:

Email:1440816890@qq.com

Website:www.qdjnkj.com

Address: Zhongtang town Zhancui Nan di Industrial area

Tools/materials

Boundary insulation strip, extruded plate, mirror reflection film, clip nail, coil tube, insulation sleeve, aluminum foil glue, water separator, raw material belt, etc

Art knife, ruler, broom, nail gun, tape measure, etc

Steps/specifications

I. ground insulation system construction preparation:

1.1

Before the ground insulation system is laid, it shall be ensured that the civil ground walls have been completed and the foundation has been levelled. There is no other work under construction in the site.

1.2

The temperature in the construction room should meet the requirements of the used pipe, because the ambient temperature is closely related to the bending radius of the pipe.

1.3

Clean the ground and wall, use level to check the flatness of the ground, the height difference within 1 meter is less than or equal to 5 mm. The wall or the protruding part of the ground is removed with a shovel, and the ground pit is filled with concrete.

1.4

Toilet and villa ground floor should make waterproof layer or lay moistureproof film.

Construction of special boundary insulation strip for floor heating

2.1

Clean the wall before laying the boundary insulation strip to ensure the flatness of the wall and avoid the strip falling off during construction and use.

2.2

The boundary insulation strips shall be pasted on all the walls and cylinders in the heating area where they intersect with the ground. The boundary insulation strips shall have excellent adhesion fastness to ensure that they will not fall off during use.

2.3

The boundary insulation strip has a thickness of 8 mm, and the boundary insulation strip should have a certain degree of elasticity to ensure that the backfill layer plays the role of buffer after heat storage and expansion, and the maximum compression is 5 mm. The cut extruded sheet is not allowed to replace the boundary insulation strip.

2.4

Joints of boundary insulation strips shall be overlapped, and the length of the overlapped shall not be less than 3 cm.

Three, floor heating special environmental protection extrusion board laying

3.1

Extruded panels should be made sure that the original floor is flat before laying.

3.2

Extruded plate should be selected density, compressive strength, thermal conductivity can meet the requirements of the technical specifications in the heating. Conventional area laid extruded sheet 2 cm thickness can be used, for the ** environment or poor thermal insulation area should be used more than 2 cm thickness.

3.3

As far as possible to choose the specifications of the extruded plate neat, reduce more patchwork.

3.4

The connecting gap between the extruded board and the boundary insulation strip should be adhered with aluminum foil tape to prevent more heat from escaping through the wall edge gap. Aluminum foil adhesive tape should also be used between the two extruded plates to ensure the overall sealing of the system.

3.5

During the laying of the extruded sheet, it is necessary to avoid large gaps caused by wire pipes or other pipes, and polyurethane foaming shall be adopted.

3.6

The laid of extrusion sheet should use whole sheet to lay all round, cut sheet to lay the principle in the middle.

3.7

The gap of extrusion board laid should not be greater than 5mm, extrusion board laid should pay attention to the flatness of the plate surface, the difference between high and low should be less than 5mm.

Four, floor heating special reflector laying

4.1

Due to the use of reflective film environment, in the selection of reflective film should be chosen to resist alkaline products.

4.2

The laying of reflective film should be flat to reduce the fold as much as possible.

4.3

Reflective film should be covered tightly, no insulation board and floor leakage spread phenomenon.

4.4

The reflective film should be laid in neat squares to facilitate the calculation of the spacing between floor heating pipes or heating cables.

4.5

Reflective film joint also want to use aluminum foil adhesive tape, to avoid taking over more material waste.

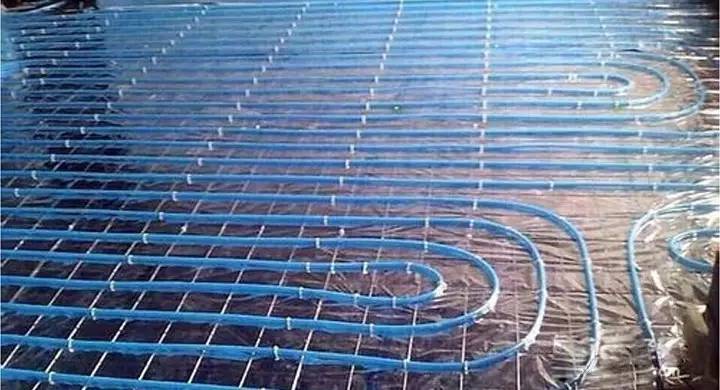

Five, floor heating special card construction

5.1

Do not use recycled materials to make out the card nail, harmful to human body.

5.2

The material of clip nail should meet the basic requirements of high strength and good creep performance. With the help of a nail gun construction nail strength requirements higher, can withstand mechanical installation.

5.3

The straight line distance pin can be used every 40-50cm card, turning to ensure that the bending radius requirements should be using 5 carding fixed.

5.4

Pay attention to the card nail installation should be straight card into the insulation layer, do not tilt the card nail to avoid bad fixing effect.

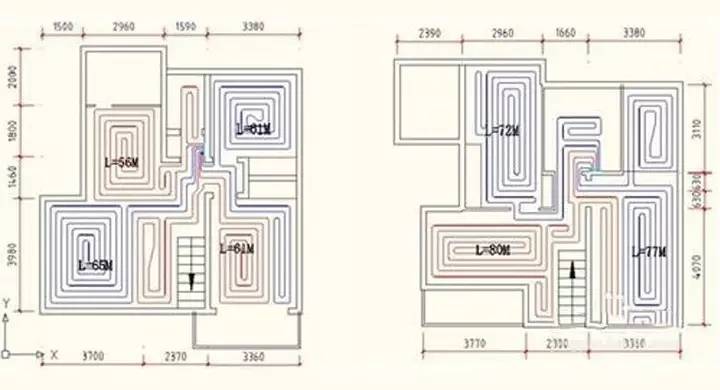

Construction of ground pipelines

6.1

Arrange the pipe according to the design drawing, and determine the pipe spacing and pipe direction. The error of the straight pipe installation spacing is less than or equal to 1cm.

6.2

Wear flat shoes whenever possible during piping construction.

6.3

There should be no joints in one circuit, and there are limits on the length of each circuit. The maximum laying length of a loop of pipe shall be less than 90m; The maximum length of a loop shall be less than 120m.

6.4

During the construction, it is forbidden to excessively twist the pipe, and the radius of pipe bending should not be less than 6 times the outer diameter of the pipe.

6.5

After the completion of the laying, it is strictly prohibited to step on or damage the pipeline.

Construction of expansion joint

7.1

When the construction area on the ground is more than 30 square meters or the side length is more than 6 meters, the expansion joints shall be set according to the spacing not more than 6 meters.

7.2

The height of the expansion joint is from the upper edge of the extruded plate to the upper edge of the backfill layer.

7.3

If the floor is paved with marble or tile, the expansion joint is best placed under the tile patchwork.

Eight, floor heating special raw material belt construction

8.1

Thread joint should use raw material to achieve high quality sealing effect.

8.2

The winding number of raw material belt should not be too much to prevent damage to the joint.

8.3

The density and thickness of the special raw material belt for ground heating are higher than that of the commercial raw material belt. The construction of the raw material belt should be wound clockwise. The winding thickness of the wire mouth is generally from thick to thin.

Construction of pipe bender and heat preservation pipe for floor heating

9.1

There is a certain height between the floor heating water separator and the ground. Generally, the pipe entering the ground by the water separator should use the protection pipe bender to fix and protect the ground coil from being damaged.

9.2

Do not use or use metal pipe bender, cause more damage to the pipeline, the use of high strength plastic pipe bender is recommended.

9.3

The water supply and return water pipes exposed at the water divider shall use insulation sleeve.

9.4

There are dense underground heating pipes at the water divider, so insulation sleeve should be used to prevent local temperature from being too high. Generally add sleeve in the supply pipeline, whether the backwater needs to add sleeve according to the length of the pipeline. The length of the insulation sleeve shall be used to the point where the distance between the two pipes is more than 10 cm.

9.5

Each pipe should be equipped with a pipe bender, insulation sleeve and separate use.

Construction of concrete backfill

10.1

The minimum thickness of concrete backfill shall not be less than 5CM.

10.2

The proportion of concrete in backfill shall strictly follow the proportion standard of "standard for sand and stone quality and test methods for common concrete".

10.3

The construction of the concrete filling layer shall be completed within 48 hours after the installation of the heating pipe and the qualified hydraulic test

10.4

Mechanical vibrating equipment is strictly prohibited in the construction of concrete filled layer. Construction personnel should wear shoes with soft soles and flat head shovels

Ten, hang fireplace to install

1. According to the size of the wall hanging furnace, the size reserved before installation, the position of the flue, and the accurate position after calibration, the furnace is hung.

2, the wall hanging furnace under the interface is connected with a hose.

Remark:

The power of wall hanging furnace is simple calculation method: every kilowatt take 7 square, for example 24 kilowatt wall hanging furnace, can take 24*7=168 square heating area, the heating area of the user is below 168 square meters, can choose 24 kilowatt wall hanging furnace, the principle that chooses wall hanging furnace is better big than small. The pump head of the wall hanging furnace is generally 10, so, the wall hanging furnace can take the floor heating of three floors at most, the heating level and wall hanging furnace height difference more than 10 meters, must add auxiliary circulation pump, or the use of the water divider with circulation pump. Wall hanging furnace with domestic hot water, if the user has a toilet with 24KW wall hanging furnace, if the user has two to three toilets with 28KW wall hanging furnace.

Construction of concrete backfill

10.1

The minimum thickness of concrete backfill shall not be less than 5CM.

10.2

The proportion of concrete in backfill shall strictly follow the proportion standard of "standard for sand and stone quality and test methods for common concrete".

10.3

The construction of the concrete filling layer shall be completed within 48 hours after the installation of the heating pipe and the qualified hydraulic test

10.4

Mechanical vibrating equipment is strictly prohibited in the construction of concrete filled layer. Construction personnel should wear shoes with soft soles and flat head shovels